PRECISION MACHINING

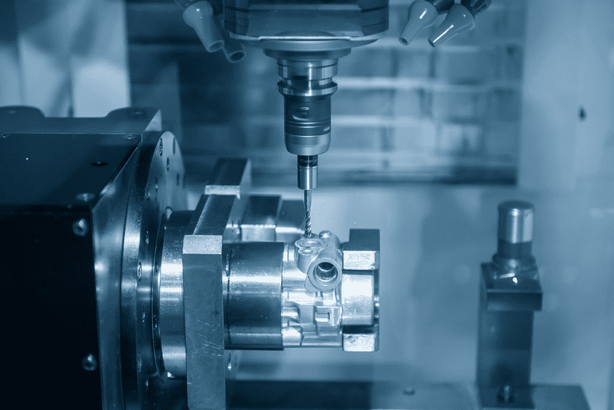

GM Aerotech is committed to delivering exceptional quality through cutting-edge technology and comprehensive machining capabilities. With a relentless focus on continual investment, we ensure both competitiveness and fast lead times across all our projects. Our state-of-the-art fleet of over 36 CNC machines offers unmatched flexibility, enabling us to handle a wide range of complexities, dimensions, and pricing requirements, tailored to meet our customers diverse needs.

Our expertise spans from producing ultra-small parts — as tiny as a pen tip — to larger components reaching up to 1 meter in length. A key advantage that sets us apart is our ability to machine with ultra-high precision, achieving accuracy down to an impressive 5 microns.

Our Services Include:

At GM Aerotech we combine cutting-edge design engineering with advanced CNC machining to deliver precise, high-performance components tailored to your specific requirements. Whether you need a prototype or full-scale production, our integrated Designing and CNC Machining services ensure the highest level of accuracy, quality, and efficiency.

Comprehensive Component Design

: Our design team brings your ideas to life with detailed 3D modeling and simulations using the latest CAD (Computer-Aided Design) software. We focus on creating designs that not only meet your functional and aesthetic requirements but also optimize for manufacturability and cost efficiency.

Advanced CNC Machining

: Our CNC machining capabilities are at the core of our precision manufacturing process. Using multi-axis CNC machines, we create complex, high-precision parts with tight tolerances and exceptional surface finishes. This includes CNC milling, turning, and drilling for various materials.

CNC Machining Capabilities:

3-Axis and 5-Axis CNC Machining

y: Our 5-axis CNC machining allows for the creation of complex geometries in a single setup, reducing production time and increasing accuracy.

CNC Turning

: Well-implemented QA processes help streamline production by identifying inefficiencies and eliminating bottlenecks, improving overall productivity.

We specialize in creating complex turned parts with tight tolerances, intricate designs, and smooth finishes. Whether you're looking for simple components or more advanced geometries, our CNC turning capabilities allow for precise machining to meet the highest industry standards. Our multi-axis CNC turning centers offer advanced machining capabilities, allowing for the creation of intricate parts with complex contours in fewer setups. This increases both efficiency and accuracy while reducing lead times.

we are committed to delivering the highest quality CNC turned parts with precision, speed, and cost-effectiveness. Our advanced CNC turning capabilities, combined with our skilled team and stringent quality control processes, ensure that every part we produce meets your exact specifications.

CNC Milling: services provide the highest level of precision and versatility for creating intricate components across a wide range of industries. By using advanced multi-axis CNC milling machines, we can manufacture complex parts with excellent accuracy, tight tolerances, and superior surface finishes. Whether you require a one-off prototype or full-scale production, we are dedicated to delivering parts that meet your exact specifications.

We offer 3-axis, 4-axis, and 5-axis CNC milling, allowing us to produce complex geometries in a single setup. Our 5-axis machines enable the creation of parts with highly intricate details, reducing the need for multiple setups and increasing accuracy. We routinely achieve tolerances as tight as ±0.001mm, making our services ideal for industries where accuracy is critical.

We offer 3-axis, 4-axis, and 5-axis CNC milling, allowing us to produce complex geometries in a single setup. Our 5-axis machines enable the creation of parts with highly intricate details, reducing the need for multiple setups and increasing accuracy. We routinely achieve tolerances as tight as ±0.001mm, making our services ideal for industries where accuracy is critical.

Grinding: Our precision grinding services ensure tight tolerances and smooth finishes on various components. Whether it's surface, cylindrical, or centerless grinding, we are equipped to handle both small and large-scale projects, ensuring precision every time.

Sparking (Electrical Discharge Machining - EDM): Our EDM services provide precision machining for hard materials or intricate geometries. Sparking or EDM is ideal for creating complex shapes, small holes, and cutting hard metals that are difficult to machine with conventional methods.

Wire Cutting (Wire EDM): Our Wire EDM services provide the capability to cut intricate shapes with extreme accuracy. This process is ideal for manufacturing parts that require high precision, complex geometries, or fine detailing.

Plating Services: In addition to our machining services, we offer a variety of plating options to enhance the durability, corrosion resistance, and appearance of your parts.